This film will tell you all you need to know about Keppels.

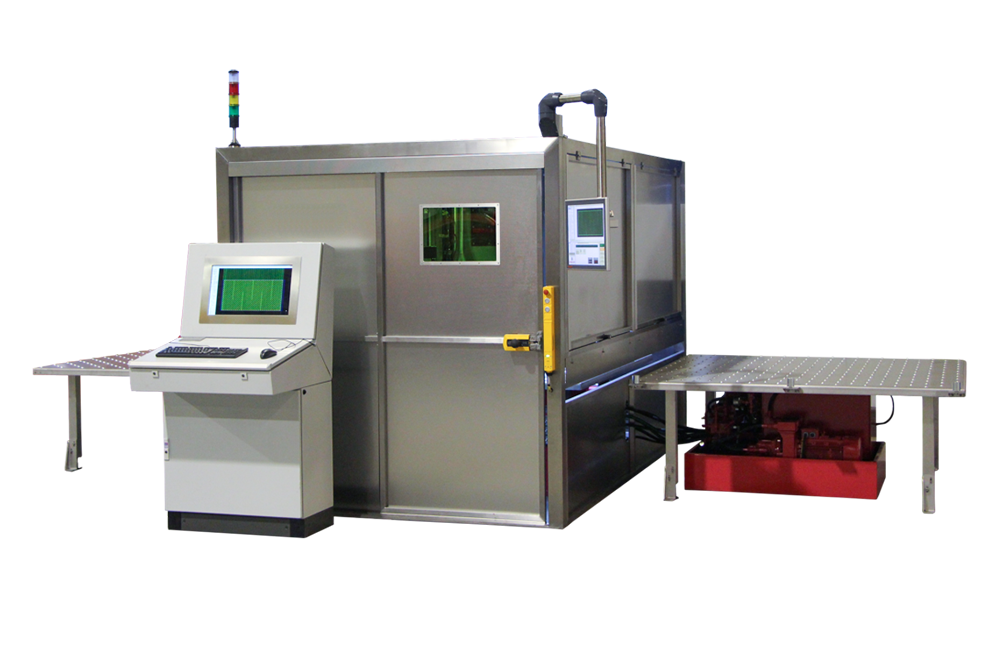

“Since we started using Beckhoff and the CX2040 as our control platform, and with the benefit of communication via Ethernet, we are able to offer a wide range of additional features in our laser welding machine,” recalls Henk-Jan Keppels.